Reasonable price for Automatic Apron Chain Conveyor - Static Pressure Automatic Moulding Line of Green Sand – Kailong Machinery Detail:

Static pressure moulding technical refers to airflow with hydraulic multi-piston squeeze compaction technology, according to the difficulty of compaction, can choose only hydraulic multi-piston squeeze compaction or airflow and hydraulic multi-piston squeeze compaction.

Static Pressure has following advantages.

◆High ability for compaction sand, rigid and dense mould, suitable to manufacture of complex castings.

◆Dimensional stability and better surface roughness.

◆High efficiency of moulding.

◆Mould plate with high rate of utilization.

◆Good working condition and labour saving.

Kailong Machinery is committed to providing customers with the most valuable Static Pressure Automatic Moulding Line, to ensure the moulding line work effectively and reliably by high performance of configuration.

–The mechanical parts of main and auxiliary equipments machining by CNC machine, the necessary heat treatment to guarantee precision and service life.

–PLC from SimensS7, with touch screen and network Ethernet etc.

–Servo system from SEW or Siemens and and Variable-Frequency Drive from Rexroth.

–Hydraulic valve of moulding machine from Rexroth, Hydraulic Cylinder from China famous brand.

–Low-voltage electrical components from Schneide.

–Hydraulic Seals from international brand.

–Bearing from China famous brand (HRB/LYC/ZWZ).

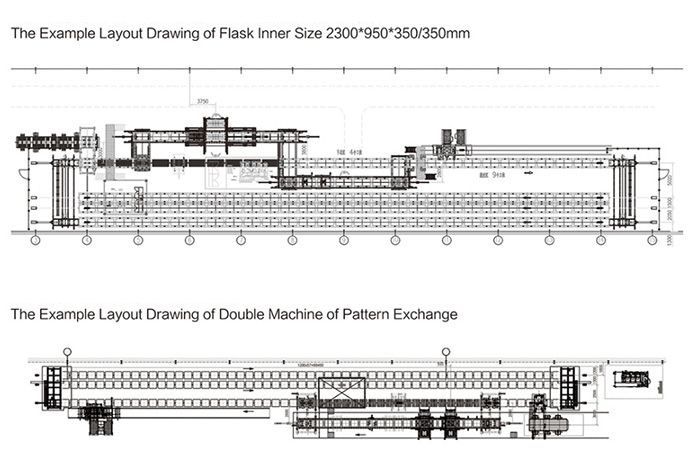

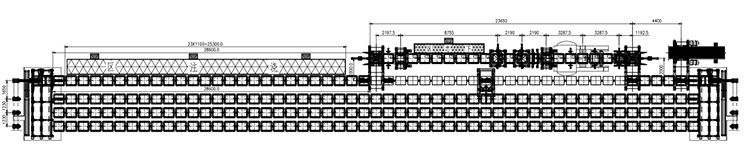

The Example Layout Drawing of Single-Station Machine of Pattern Turnover:

Typical Specification of Single-Station Moulding Line

| Item | Model | |||

| KSP80 | KSP100 | KSP120 | KSP230 | |

| Flask Inner Size(mm) | 800x600x200/200 | 1000x1000x250/250 | 1200x800x350/350 | 2300x950x350/350 |

| Moulding Speed(sec/cycle) | 30 | 30 | 36 | 60 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 | 8~12 |

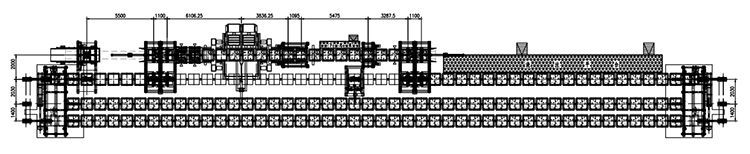

The Example Layout Drawing of Double-Station Machine of Pattern Exchange

Typical Specification of Double-Station Moulding Line

| Item | Model | ||

| SPD80 | SPD100 | SPD120 | |

| Flask Inner Size(mm) | 800x600x200/200 | 1000x1000x250/250 | 1200x800x350/350 |

| Moulding Speed(sec/cycle) | 20 | 20 | 24 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 |

Product detail pictures:

Related Product Guide:

Modern Era Molding Machines and Industrial Machines

What Do You Need To Know About Your Injection Moulding Machine?

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for Reasonable price for Automatic Apron Chain Conveyor - Static Pressure Automatic Moulding Line of Green Sand – Kailong Machinery, The product will supply to all over the world, such as: Croatia , moldova , Myanmar , We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable products quality , increase customers' satisfaction and achieve win-win situation .

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

-

Manufacturing Companies for Food Mixer Machine ...

View Detail -

PriceList for Manual Candle Machine - Static P...

View Detail -

Low price for Machine A Glacons Cube - Flask f...

View Detail -

China New Product E Liquid Monodoses Pouring Ma...

View Detail -

Best-Selling Chocolate Chips Depositing Machine...

View Detail -

Top Quality Vertical Chain Conveyor - Flask fo...

View Detail