Professional China Cap Compression Moulding Machine - Semi-Automatic Pouring Machine – Kailong Machinery Detail:

Semi-automatic pouring machine is suited for work in semi-automatic mode,guided by operator with joystick. consist of fan-shaped pouring ladle, servo tilting mechanism, longitudinal vehicle rail system, transferring system,control and operation system,safe system, cable device, stream inoculation device, etc. With three freedom of longitudinal travels,transverse travels and tilt pouring , it’s widely used in all kinds of moulding line for grey iron, ductile iron,included flask moulding and none-flask moulding line.

Ladle transport: By crane or forklift.

Ladle capacity: 1000kg-2500kg.

Pouring speed: 15-22kg/sec.

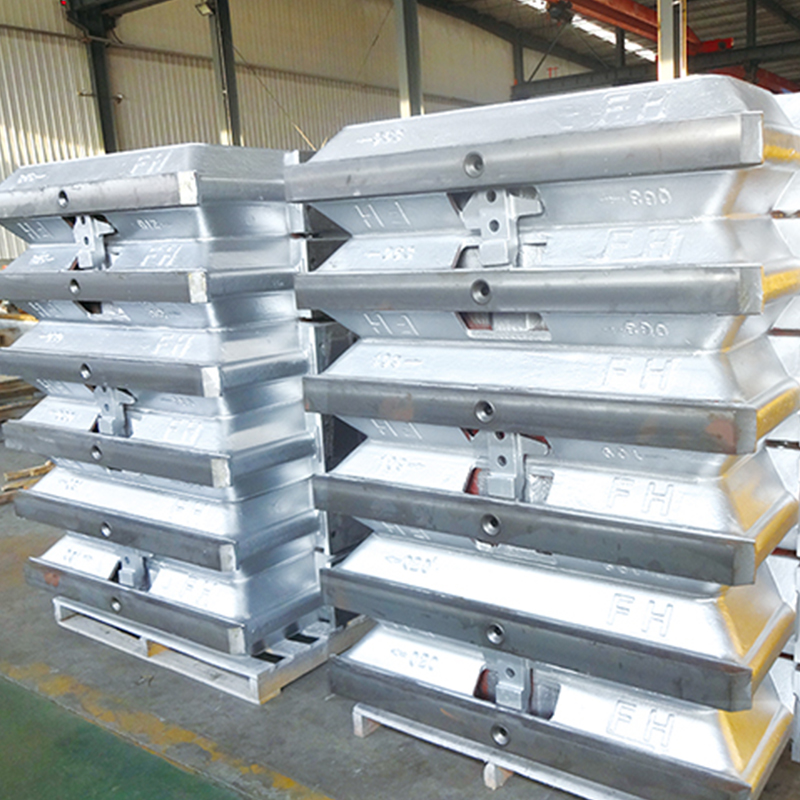

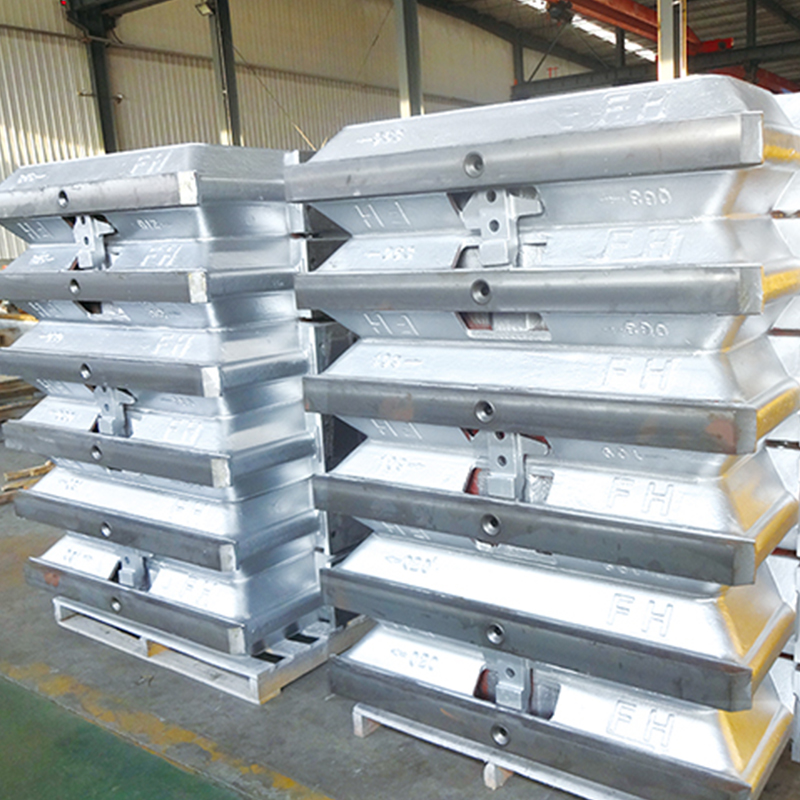

Product detail pictures:

Related Product Guide:

How Does an Injection Moulding Machine Work?

What is Injection Moulding?

We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for Professional China Cap Compression Moulding Machine - Semi-Automatic Pouring Machine – Kailong Machinery, The product will supply to all over the world, such as: Hanover , Munich , Georgia , With a fully integrated operation system, our company has won a good fame for our high quality goods, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of Credit first and customer supremacy, we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.

-

Low MOQ for Chocolate Moulding Machine - Flask...

View Detail -

PriceList for Plastic Injection Molding Machine...

View Detail -

High reputation Glue Dispenser Robot - Open Me...

View Detail -

Cheapest Factory Resin Sand Mixer Machine - Au...

View Detail -

Factory wholesale Bottle Cap Making Machine - ...

View Detail -

Quality Inspection for Pvc Pipe Die Head - Fla...

View Detail