High Quality Styrofoam Shape Moulding Machine - Automatic Horizontal Flaskless Moulding Machine – Kailong Machinery Detail:

Typical Specification of Moulding Machine

| Item | Model | ||

| KSF50 | KSF60 | KSF70 | |

| Flask Inner Size(mm) | 500x400x150/150 | 600x500x200/200 | 700x600x250/250 |

| Moulding Speed(Without Core Setting)(sec/cycle) | 30 | 30 | 36 |

| Squeeze Surface Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 |

| Hardness of Horizontal Surface & Parting Surface |

80°~92°(GF Hardness Tester) | ||

| Hardness of Mold Side | 85°~90°(GF Hardness Tester) | ||

| Moulding Rate | ≥98% | ||

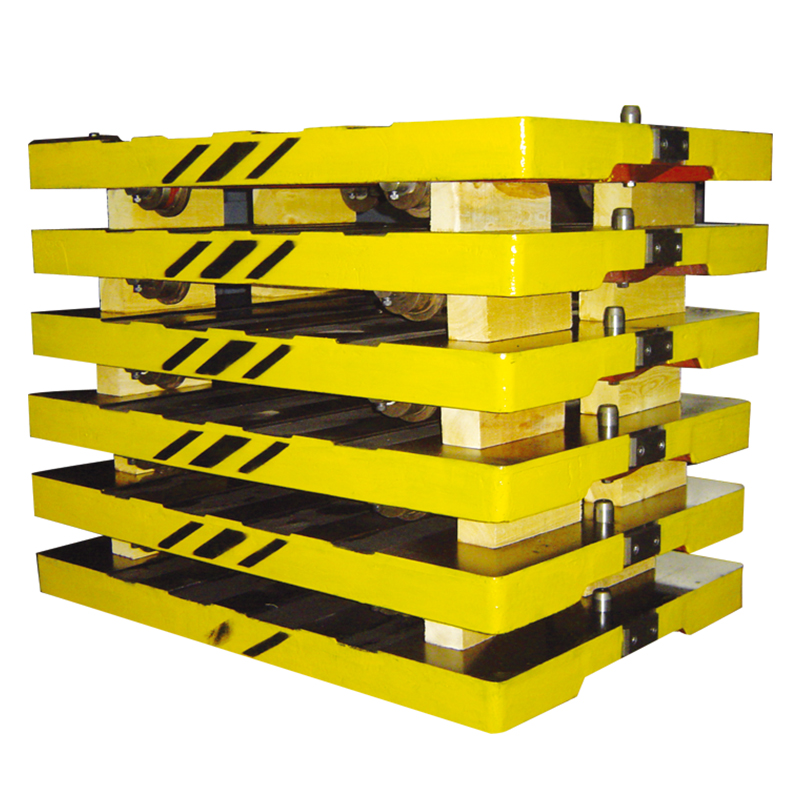

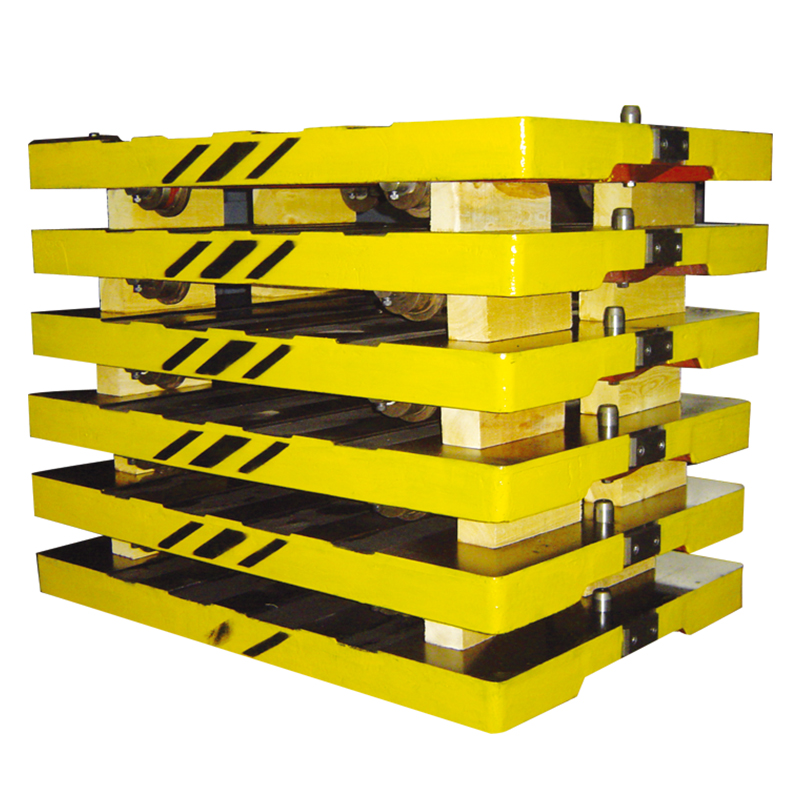

KSF horizontal parting and flask-striped shooting-squeezing molding line adopt the sand shooting, with horizontal parting, slip flask and weight. Easy core setting, easy operation, high automation, the molding lines are widely used in mass-production for small-sized castings. The whole line consist of molding machine, sand conveyor line, slip flask and weight taking and droping device, indexing transport and cushioning device, synchronous cooling belt, pouring machine, etc.

Product detail pictures:

Related Product Guide:

What is Injection Moulding?

Injection Moulding Design and Tooling

Our personnel are generally within the spirit of continuous improvement and excellence, and using the excellent top quality goods, favorable rate and superior after-sales expert services, we try to win every customer's believe in for High Quality Styrofoam Shape Moulding Machine - Automatic Horizontal Flaskless Moulding Machine – Kailong Machinery, The product will supply to all over the world, such as: Azerbaijan , Swiss , Malaysia , Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

-

Best Price on Lcd Repair Machine Pour Iphone 6 ...

View Detail -

Factory Outlets Biscuit Production Line Price -...

View Detail -

High Quality for Automatic Chocolate Pouring Ma...

View Detail -

Lowest Price for Chain Apron Conveyor - High Q...

View Detail -

Factory Outlets Leveling Shear Line - High Qua...

View Detail -

Fast delivery Automatic Molding Machine - Pall...

View Detail