High Quality Stainless Steel Conveyor Chain - Automatic Horizontal Flaskless Moulding Line – Kailong Machinery Detail:

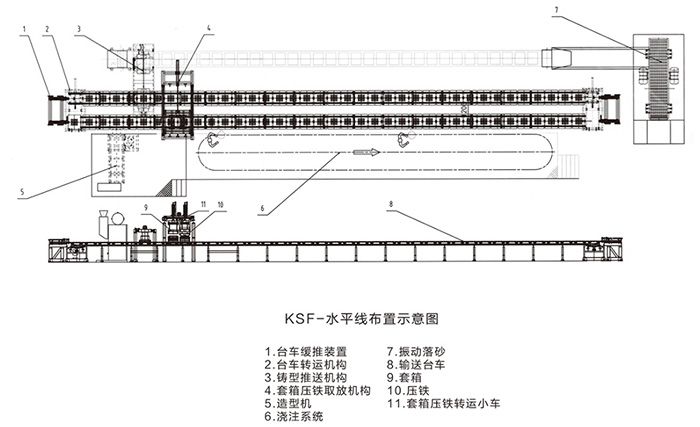

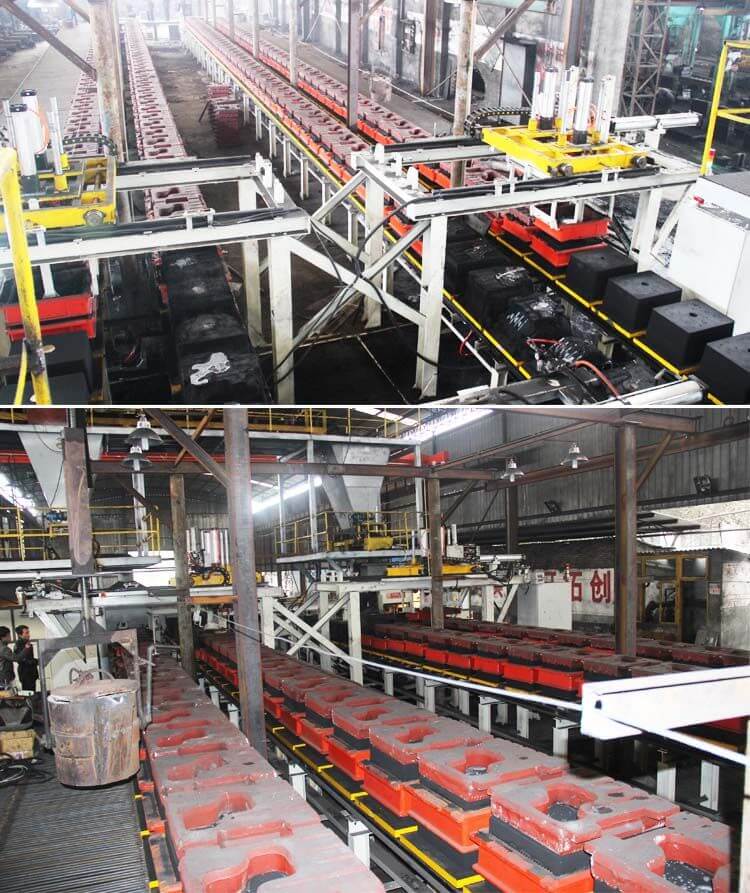

KSF horizontal parting and flask-striped shooting-squeezing molding line adopt the sand shooting, with horizontal parting, slip flask and weight. Easy core setting, easy operation, high automation, the molding lines are widely used in mass-production for small-sized castings. The whole line consist of molding machine, sand conveyor line, slip flask and weight taking and droping device, indexing transport and cushioning device, synchronous cooling belt, pouring machine, etc.

Typical Specification of Moulding Machine

| Item | Model | ||

| KSF50 | KSF60 | KSF70 | |

| Flask Inner Size(mm) | 500x400x150/150 | 600x500x200/200 | 700x600x250/250 |

| Moulding Speed(Without Core Setting) | 30 | 30 | 36 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 |

Product detail pictures:

Related Product Guide:

Modern Era Molding Machines and Industrial Machines

How Does an Injection Moulding Machine Work?

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and growth, we're going to build a prosperous future together with your esteemed firm for High Quality Stainless Steel Conveyor Chain - Automatic Horizontal Flaskless Moulding Line – Kailong Machinery, The product will supply to all over the world, such as: San Diego , Spain , Pakistan , Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!

-

Europe style for Elastomer Pu Casting Machine -...

View Detail -

2017 High quality Standing Up Sealing Machine -...

View Detail -

Factory Cheap Hot Hydraulic Moulding Line - Au...

View Detail -

Big Discount Croquette Pour Chien Machine - Ap...

View Detail -

Massive Selection for Hdpe Pipe Machine - Auto...

View Detail -

Factory Free sample Pu Sole Making Machine - F...

View Detail